Understanding the technology and different parts can help you make an informed decision about which vape cartridge is right for you.

There are so many different types of cartridges and atomizers that it’s difficult for consumers and even canna-entrepreneurs to know which ones to choose. Here, we explain cart technology, the safest and most harmful practices, and what to look for when selecting a good option – specifically as it pertains to wetted materials (materials that come into contact with the concentrate itself) and vaping safety.

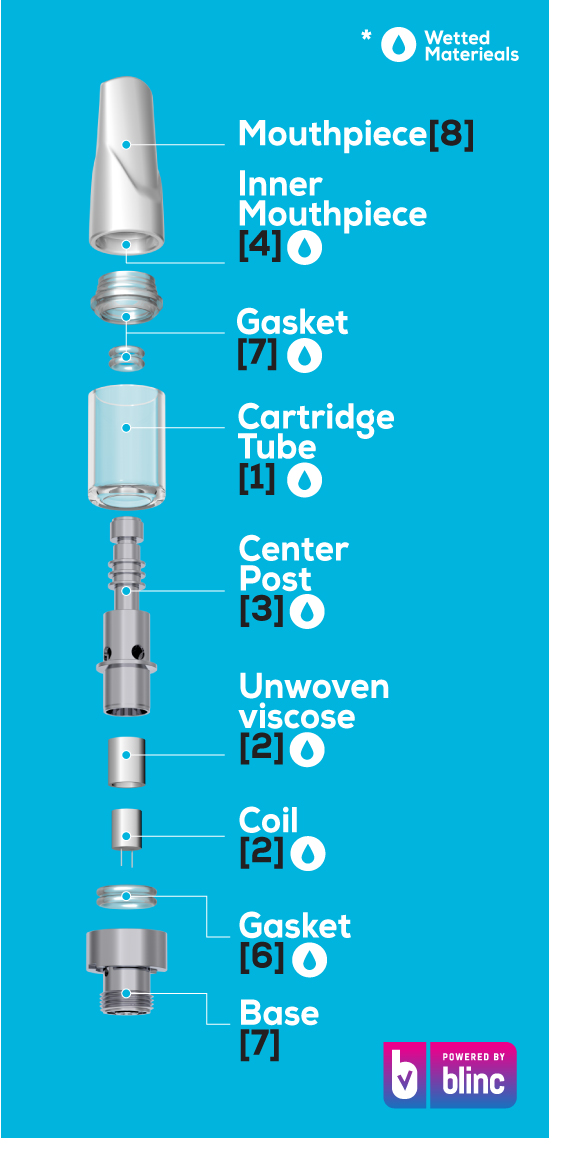

Let’s start by using this diagram as a guide.

Image 1: Cartridge Tube

Image 1: Cartridge Tube

As this is probably the component that has the most contact surface with the extract, it’s important to know what material is used. Fused Borosilicate Quartz (glass) is one of the safest materials that can be used as it can handle temperatures up to 1,100°C and isn’t prone to leaching (borosilicate quartz is even used to store nuclear waste). On the other hand, polycarbonate materials (plastics) can leach products like bisphenol-A (BPA) at higher temperatures if the extract tends to be more basic than acidic. These materials should not be used in cartridges or disposables and can pose potential health risks for consumers.

Image 2: “Cotton”

The cotton (or more accurately called the unwoven viscose) in a cartridge serves as a catalyst to the capillary action of the coils. It essentially absorbs the extract faster and gets it to the core of the cartridge which in most cases is ceramic. Simply put, it makes for faster absorption of the extract in the coil. During standard use of the cartridge, this cotton will never reach burning temperatures.

Images 3 & 4: Center Post & Inner Mouthpiece

These are the components that are most prone to leaching if not made with the right material. Traditionally, the material used is a brass alloy called H59, which itself contains a little over 2% of lead. These days, when you speak to manufacturers, they will say “lead-free”, which is a big misconception as they are mainly using another brass allot called H59-B1 or B2 that contains only 0.05% lead but can still leach. At Blinc, we’ve pioneered the use of medical-grade 304 Stainless Steel, which doesn’t contain any lead at all. Keep in mind that any finish on these materials may also contain lead (ie: gold of black electroplating).

Image 5: Coil

This is where the magic happens in any vaping device. The heating element, ie: stainless steel, kanthal or nichrome) will provide heat up to a certain temperature when a certain voltage is applied to it applied depending on its resistance. That heat will reach the oil that has been absorbed by the wicking material, ie: ceramic, quartz, etc… which will allow the oil to be “vaporized” into and aerosol. The key factors here that influence this process are the consistency and purity of the materials used, from which are derived the temperatures. A secondary factor is also the intensity and length of the puff (the vaping profile).

Images 6 & 7: Sealing Gaskets

Silicone offers good low and high-temperature capability, while maintaining superior flexibility, low toxicity, low odor, lower molding pressures, and very low extractables (leaching characteristics). These joints serve 2 purposes: the main one being to avoid leaking, but they secure the components in place. The type of silicone is important, as most silicone gaskets have a serviceable temperature range from -55 °C to 200 °C. Keep in mind that when using a proper vaping cartridge and battery, with the cutoff times, the temperature should never go over 200 °C.

When purchasing vape products, especially cartridges, it’s important to understand that every material is important: specifically wetted materials. At Blinc, we provide you with full analysis, reports, and certifications on each component. We can do this because we are the only manufacturer that controls the entire supply chain: our team in Shenzhen audits each raw material supplier every 6 months. Whether your work with a Blinc representative or with any other manufacturer, make sure you do your due diligence and request more information on any ISO, GMP or FDA certifications.

#notjustvapor

—

Link to original article: https://www.greenentrepreneur.com/article/371830